1

Detail of George Jackson Ltd, Kimpton Park Way (4)

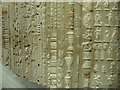

The factory is a treasure trove of plasterwork. Every square inch is filled with materials, moulds or devices geared to producing decorative elements such as cornices, columns, ceiling roses, architraves, picture frames, dado rails and the like. Traditional craftsmanship is still paramount as most of the work is done by hand rather than by computerised machine.

Two longstanding techniques are still employed - composition mouldings and fibrous plasterwork. Composition, known colloquially as "compo" and resembling putty, is pressed into reverse moulds. It remains flexible whilst pressed into position but hardens once fixed in place. The company claims to have over 11,000 boxwood moulds. Fibrous plaster consists of a plaster cast reinforced with fabric, often hessian, to which timber laths are affixed. The cast is fixed to the wall or ceiling using adhesive, screws or wires and rackets.

The company can trace its roots back to 1763 when Thomas Jackson began trading in Tottenham Court Road. The Jacksons' presence continued until 1947 and after several changes of ownership, including being subsumed into Skanska UK, the company currently operates as an independent business. During all that time, it has worked on the Royal Pavilion, Buckingham Palace, SS Great Britain, numerous London theatres and Windsor Castle. More information can be found at their website: www.georgejackson.com .

The factory is not routinely open to the public - this picture was taken during a visit organised by the Georgian Group.

Image: © Stephen Richards

Taken: 24 Oct 2012

0.04 miles

2

Detail of George Jackson Ltd, Kimpton Park Way (3)

The factory is a treasure trove of plasterwork. Every square inch is filled with materials, moulds or devices geared to producing decorative elements such as cornices, columns, ceiling roses, architraves, picture frames, dado rails and the like. Traditional craftsmanship is still paramount as most of the work is done by hand rather than by computerised machine.

Two longstanding techniques are still employed - composition mouldings and fibrous plasterwork. Composition, known colloquially as "compo" and resembling putty, is pressed into reverse moulds. It remains flexible whilst pressed into position but hardens once fixed in place. The company claims to have over 11,000 boxwood moulds. Fibrous plaster consists of a plaster cast reinforced with fabric, often hessian, to which timber laths are affixed. The cast is fixed to the wall or ceiling using adhesive, screws or wires and rackets.

The company can trace its roots back to 1763 when Thomas Jackson began trading in Tottenham Court Road. The Jacksons' presence continued until 1947 and after several changes of ownership, including being subsumed into Skanska UK, the company currently operates as an independent business. During all that time, it has worked on the Royal Pavilion, Buckingham Palace, SS Great Britain, numerous London theatres and Windsor Castle. More information can be found at their website: www.georgejackson.com .

The factory is not routinely open to the public - this picture was taken during a visit organised by the Georgian Group.

Image: © Stephen Richards

Taken: 24 Oct 2012

0.04 miles

3

Detail of George Jackson Ltd, Kimpton Park Way (2)

The factory is a treasure trove of plasterwork. Every square inch is filled with materials, moulds or devices geared to producing decorative elements such as cornices, columns, ceiling roses, architraves, picture frames, dado rails and the like. Traditional craftsmanship is still paramount as most of the work is done by hand rather than by computerised machine.

Two longstanding techniques are still employed - composition mouldings and fibrous plasterwork. Composition, known colloquially as "compo" and resembling putty, is pressed into reverse moulds. It remains flexible whilst pressed into position but hardens once fixed in place. The company claims to have over 11,000 boxwood moulds. Fibrous plaster consists of a plaster cast reinforced with fabric, often hessian, to which timber laths are affixed. The cast is fixed to the wall or ceiling using adhesive, screws or wires and rackets.

The company can trace its roots back to 1763 when Thomas Jackson began trading in Tottenham Court Road. The Jacksons' presence continued until 1947 and after several changes of ownership, including being subsumed into Skanska UK, the company currently operates as an independent business. During all that time, it has worked on the Royal Pavilion, Buckingham Palace, SS Great Britain, numerous London theatres and Windsor Castle. More information can be found at their website: www.georgejackson.com .

The factory is not routinely open to the public - this picture was taken during a visit organised by the Georgian Group.

Image: © Stephen Richards

Taken: 24 Oct 2012

0.04 miles

4

Detail of George Jackson Ltd, Kimpton Park Way (5)

The factory is a treasure trove of plasterwork. Every square inch is filled with materials, moulds or devices geared to producing decorative elements such as cornices, columns, ceiling roses, architraves, picture frames, dado rails and the like. Traditional craftsmanship is still paramount as most of the work is done by hand rather than by computerised machine.

Two longstanding techniques are still employed - composition mouldings and fibrous plasterwork. Composition, known colloquially as "compo" and resembling putty, is pressed into reverse moulds (as seen here to produce an egg-and-dart moulding). It remains flexible whilst pressed into position but hardens once fixed in place. The company claims to have over 11,000 boxwood moulds. Fibrous plaster consists of a plaster cast reinforced with fabric, often hessian, to which timber laths are affixed. The cast is fixed to the wall or ceiling using adhesive, screws or wires and rackets.

The company can trace its roots back to 1763 when Thomas Jackson began trading in Tottenham Court Road. The Jacksons' presence continued until 1947 and after several changes of ownership, including being subsumed into Skanska UK, the company currently operates as an independent business. During all that time, it has worked on the Royal Pavilion, Buckingham Palace, SS Great Britain, numerous London theatres and Windsor Castle. More information can be found at their website: www.georgejackson.com .

The factory is not routinely open to the public - this picture was taken during a visit organised by the Georgian Group.

Image: © Stephen Richards

Taken: 24 Oct 2012

0.04 miles

5

Detail of George Jackson Ltd, Kimpton Park Way (1)

The factory is a treasure trove of plasterwork. Every square inch is filled with materials, moulds or devices geared to producing decorative elements such as cornices, columns, ceiling roses, architraves, picture frames, dado rails and the like. Traditional craftsmanship is still paramount as most of the work is done by hand rather than by computerised machine.

Two longstanding techniques are still employed - composition mouldings and fibrous plasterwork. Composition, known colloquially as "compo" and resembling putty, is pressed into reverse moulds. It remains flexible whilst pressed into position but hardens once fixed in place. The company claims to have over 11,000 boxwood moulds. Fibrous plaster consists of a plaster cast reinforced with fabric, often hessian, to which timber laths are affixed. The cast is fixed to the wall or ceiling using adhesive, screws or wires and rackets.

The company can trace its roots back to 1763 when Thomas Jackson began trading in Tottenham Court Road. The Jacksons' presence continued until 1947 and after several changes of ownership, including being subsumed into Skanska UK, the company currently operates as an independent business. During all that time, it has worked on the Royal Pavilion, Buckingham Palace, SS Great Britain, numerous London theatres and Windsor Castle. More information can be found at their website: www.georgejackson.com .

The factory is not routinely open to the public - this picture was taken during a visit organised by the Georgian Group.

Image: © Stephen Richards

Taken: 24 Oct 2012

0.04 miles

6

Kimpton Industrial Park, Sutton

Richmond Plastics and other businesses from Kimpton Road.

Image: © Michael Garlick

Taken: 7 Nov 2013

0.06 miles

7

View from footpath to Kimpton Industrial Park

A trail runs along a ridge that could be an old railway embankment.

Image: © James Emmans

Taken: 11 May 2020

0.07 miles

8

Kimpton Industrial Park, Sutton

Designplan Lighting from the rear.

Image: © Michael Garlick

Taken: 7 Nov 2013

0.08 miles

9

Kimpton Industrial Park, Sutton

Designplan Lighting in Wealdstone Road.

Image: © Michael Garlick

Taken: 7 Nov 2013

0.12 miles

10

Kimpton Industrial Park, Sutton

Looking northwards to Designplan Lighting in Wealdstone Road.

Image: © Michael Garlick

Taken: 7 Nov 2013

0.12 miles