1

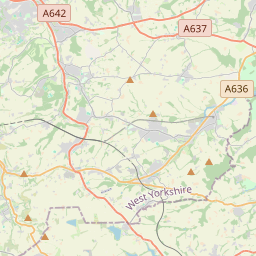

Businesses on Wakefield Road (A636), Scissett

Image: © JThomas

Taken: 12 Oct 2019

0.01 miles

2

Nortonthorpe Mills, Scissett - steam engine

This is Violet - a horizontal tandem compound engine by Pollit and Wigzell of Sowerby Bridge. Originally built in 1886 and rebuilt with a new Corliss valve high pressure cylinder and smaller low pressure cylinder in 1931. The cylinders are now 13.25" and 25.25" bores by 5' stroke. As rebuilt it took steam at 120 pounds per square inch and generated 250 horsepower at 55 rpm. After 1970 the engine was on standby to drive a generator but the company went into receivership in 1984 and by 1990 the engine was well disused. It was restored later and returned to steam for a period but I have not seen it since about 2006 when it was in good order but not in steam.

This is the makers plate on the rear of the combined jet condenser and air pump assembly.

Image: © Chris Allen

Taken: 29 May 1990

0.03 miles

3

Nortonthorpe Mills, Scissett - steam engine

This is Violet - a horizontal tandem compound engine by Pollit and Wigzell of Sowerby Bridge. Originally built in 1886 and rebuilt with a new Corliss valve high pressure cylinder and smaller low pressure cylinder in 1931. The cylinders are now 13.25" and 25.25" bores by 5' stroke. As rebuilt it took steam at 120 pounds per square inch and generated 250 horsepower at 55 rpm. After 1970 the engine was on standby to drive a generator but the company went into receivership in 1984 and by 1990 the engine was well disused. It was restored later and returned to steam for a period but I have not seen it since about 2006 when it was in good order but not in steam.

Image: © Chris Allen

Taken: 29 May 1990

0.03 miles

4

Nortonthorpe Mills, Scissett - steam engine

This is Violet - a horizontal tandem compound engine by Pollit and Wigzell of Sowerby Bridge. Originally built in 1886 and rebuilt with a new Corliss valve high pressure cylinder and smaller low pressure cylinder in 1931. The cylinders are now 13.25" and 25.25" bores by 5' stroke. As rebuilt it took steam at 120 pounds per square inch and generated 250 horsepower at 55 rpm. After 1970 the engine was on standby to drive a generator but the company went into receivership in 1984 and by 1990 the engine was well disused. It was restored later and returned to steam for a period but I have not seen it since about 2006 when it was in good order but not in steam.

This view is from by the low pressure cylinder looking towards the crank and flywheel. This is Pollit & Wigzell's patented three rod design and one of the two low pressure piston rods is seen passing alongside the high pressure cylinder. This allowed the high and low pressure cylinders to be arranged one directly behind the other and eliminated the space needed for piston rod glands between the cylinders.

Image: © Chris Allen

Taken: 29 May 1990

0.03 miles

5

Nortonthorpe Mills, Scissett - steam engine

This is Violet - a horizontal tandem compound engine by Pollit and Wigzell of Sowerby Bridge. Originally built in 1886 and rebuilt with a new Corliss valve high pressure cylinder and smaller low pressure cylinder in 1931. The cylinders are now 13.25" and 25.25" bores by 5' stroke. As rebuilt it took steam at 120 pounds per square inch and generated 250 horsepower at 55 rpm. After 1970 the engine was on standby to drive a generator but the company went into receivership in 1984 and by 1990 the engine was well disused. It was restored later and returned to steam for a period but I have not seen it since about 2006 when it was in good order but not in steam.

This view shows the patented 'three-rod' design with two piston rods from the low pressure passing either side of the high pressure cylinder and connecting to the crosshead slide blocks. The end of the Corliss valve high pressure cylinder is seen on the left with its metallic packing for the piston rod. The governor is a Whitehead 'high-speed' type. The 14' diameter flywheel is on the right. Hidden in a wooden 'cupboard' behind the flywheel are two large spur gears that took the drive to the mill.

Image: © Chris Allen

Taken: 29 May 1990

0.03 miles

6

Nortonthorpe Mills, Scissett - steam engine

This is Violet - a horizontal tandem compound engine by Pollit and Wigzell of Sowerby Bridge. Originally built in 1886 and rebuilt with a new Corliss valve high pressure cylinder and smaller low pressure cylinder in 1931. The cylinders are now 13.25" and 25.25" bores by 5' stroke. As rebuilt it took steam at 120 pounds per square inch and generated 250 horsepower at 55 rpm. After 1970 the engine was on standby to drive a generator but the company went into receivership in 1984 and by 1990 the engine was well disused. It was restored later and returned to steam for a period but I have not seen it since about 2006 when it was in good order but not in steam.

This was an underexposed colour slide and has been improved by conversion to monochrome.

Image: © Chris Allen

Taken: 29 May 1990

0.03 miles

7

Engine house, Nortonthorpe Mills, Scissett

This is now the Nortonthorpe Industrial Park but is a former woollen mill. This fine building houses a Pollit and Wigzell horizontal tandem compound steam engine that was restored to steam operation but has now not run for many years. The engine is seen here -

Image

Image: © Chris Allen

Taken: 8 Aug 1992

0.03 miles

8

Nortonthorpe Mills - steam engine, crosshead

Part of the Pollit & Wigzell horizontal tandem compound mill engine that once powered this former woollen mill. The crosshead connects the piston rod to the connecting rod and runs in guides that constrain the piston rod to move in a straight line while the far end of the con rod describes a circle. The pot of oil lubricates the little end. This is a Pollit 'three rod' design with three piston rods. The thicker middle one that is cottered to a Y shaped piece is the high pressure rod while the thinner rods flanking it are the low pressure rods and they attach to the slide blocks with horizontal cotters. The light diagonal rod on the right drives the reducing gear that is used for taking 'indicator diagrams' to calculate the indicated horsepower.

Steam engines are apparently simple - until you get down to the details.

Image: © Chris Allen

Taken: 7 Oct 2006

0.03 miles

9

Nortonthorpe Mills - Whitehead governor

This is on the Pollit and Wigzell tandem compound mill engine and closely regulates the engine's speed by controlling the amount of steam entering the cylinders by changing the high pressure cut-off -

Image Close speed regulation was important in the textile trades and there were various governors that claimed to be capable of holding the speed consistently close to the design speed even though the load was varying. This is a clever trick as a simple governor has a specific speed for each position of the balls and hence for each cut-off position. Designs such as the Collamore attachment, the Lumb's governor with Wilby's regulator and the Whitehead governor (to name some) effectively circumvented this and the engine's speed was more or less constant over a wide load range. The Whitehead was used by Pollit and Wigzell latterly although many customers specified the Lumb's or had it retrofitted. The Whitehead looks deceptively simple but contained a second internal spring and dashpot arrangement that compensated for changes in load and speed to bring the engine back to design speed.

Image: © Chris Allen

Taken: 7 Oct 2006

0.03 miles

10

Nortonthorpe Mills - steam engine, Corliss trip gear

This is on the high pressure cylinder of a Pollit and Wigzell tandem compound steam engine. The Corliss valve was a semirotary slide valve with two steam and two exhaust valves per cylinder. The steam valves were capable of being released and closed at various points before the end of the full stroke - this is termed cut-off and is under the control of the governor that moves a cam in the valve gear that forces apart two tripping surfaces, allowing the valve to be closed briskly by a spring with a cushioning dashpot. Different manufacturers used slightly different gears and this is recognisably that of Pollit and Wigzell of Sowerby Bridge. Another feature of this builder was the placing of the high and low pressure cylinders together to reduce length and having two low pressure piston rods, one either side of the high pressure. One of the low pressure piston rods passes horizontally in the lower quarter of the picture and its gland is seen to the right. The shiny vertical cylinder seen partly on the right hand edge is the low pressure steam chest safety valve.

Image: © Chris Allen

Taken: 7 Oct 2006

0.03 miles